Cold Press Food Products

Gone are the days of choosing between full-fat, low-fat or no-fat. Nowadays, consumers have an overwhelming choice when it comes to food, with words such as organic, raw, vegan, superfood, gluten-free and many more floating around the market. And now these choices extend to the actual food-making process.To heat or not to heat, that is the question – now that cold-pressed products are becoming more popular.

Why Cold Press Technology?

01.To maintain fresh like attributes of end product

02. To retain nutritional value

03.To preserve the texture and colour

What is Cold Press Technology?

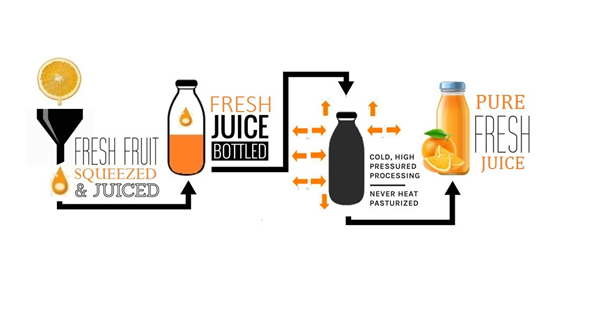

Cold pressing is a method of processing raw ingredients by first crushing fruits, vegetables or leafy greens before pressing out the juice. In order to maintain fresh-like attributes of juice, cold pressing is typically done at refrigerated temperatures and minimum exposure to oxygen.

The known fact is that cold pressed fruit and vegetable juice products are an essential source of vitamins, antioxidants, enzymes and proteins, but only when minimally processed. The product labels often include terms such as fresh, natural, no added preservatives, raw, organic, vegan, and cleansing beverages.

Cold pressed juices are fast taking over the shelves in all supermarkets. Some of the popular brands manufacturing cold pressed juices in India are:

- Raw Pressery

- Rejoov

- Juicifix

- Antidote

- Cleanse High

- Just Pressed

- Jus Divine

- Raw Leaf

“Despite the commercial success of HPP, there are other minimal processing techniques that have a potential for preservation of fresh juice products. Few of them include UV-C light processing, Pulsed Electric Field (PEF) and Ultra and High Pressure Homogenization (UHPH).”

Here’s the list for non-thermal processing methods that can be used to extend shelf life of cold pressed products:

- High Pressure Carbon Dioxide (HPCD) process

- Ultra High Pressure Homogenization (UHPH)

- Pulsed Electric Field (PEF)

- Ultraviolet (UV-C) Light

- High Hydrostatic Pressure (HPP)

Preservation

Cold pressed products can stay fresh only for 72 hours. In order to retain nutritional attributes of the raw ingredients, non thermal preservation methods can be used to obtain refrigerated shelf life of the product. One of the popular methods used for preservation is High Hydrostatic Pressure Processing (HPP).

Growing demand for more cold pressed food products

With the rise in health conscious consumers and increasing disposable income, the appetite for healthier cold pressed food products is increasing.

Here are some of the products recently added to the cold pressed shelves in the retail stores:

Food Bars: These cold pressed bars are available in many flavours. They also claim to be organic, without any stabilizers & preservatives. Some of the commonly used ingredients include oranges, carrots, pineapple, cashews, Chia seeds, coconut & ginger.

Baby Food: Cold pressed baby food is becoming popular in health conscious parents who want to ensure that proper nutrition reaches to the plates of their children.

nutrition reaches to the plates of their children.