Flavoured Milk Processing

“Flavoured milk is the milk in which some flavour and colour have been added to make it more palatable. “

With the evolving dietary habits and increase in disposable income, India’s packaged flavoured milk segment has been enjoying an increased level of interest, and this attention has brought about a significant amount of product innovation in the country.

Research from Mintelreveals that flavoured milk products accounted for 43% of dairy drink introductions in India in 2016, up from just 20% in 2012. In fact, these products are still causing a stir, with flavoured milk accounting for 39% of India’s dairy drink launches during the first half of 2017.

What is flavoured milk?

Flavoured milk is a ready to drink product which is produced from milk with added sweetener, flavours, and stabilizer in some cases.

Flavored milk drinks are available in many varieties. Viscosities range from that of whole milk, to “thick milkshake” products which achieve their viscosity through use of thickening additives, sometimes in combination with freezing. AmulKool, Mother Dairy’s Milk Shake and Gowardhan’sTopp Up Milk are few of the popular flavoured milk drinks available in the Indian market.

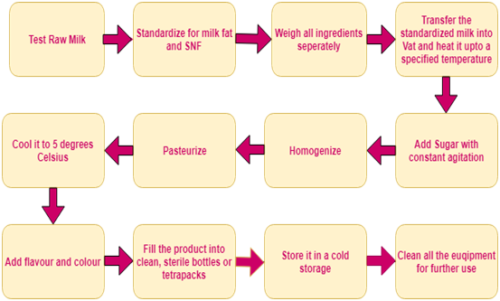

“The method of production involves standardizing the milk to the desired fat and SNF percent. It is then heated, homogenized, clarified, aspectically filled into sterile packaging material and stored in cold storage.”

Here are basic steps involved in production:

1. Testing the raw milk

2. Standardization for fat and SNF

3. Weighing the ingredients

4. Heating the standardized milk into a Vat

5. Addition of sugar

6. Homogenization

7. Pasteurization

8. Cooling

9. Addition of flavor and colour

10. Filling into bottles

11. Storage

Method of Production

Flavored milk drinks are available in many varieties. Viscosities range from that of whole milk, to “thick milkshake” products which achieve their viscosity through use of thickening additives, sometimes in combination with freezing. AmulKool, Mother Dairy’s Milk Shake and Gowardhan’sTopp Up Milk are few of the popular flavoured milk drinks available in the Indian market.

“The method of production involves standardizing the milk to the desired fat and SNF percent. It is then heated, homogenized, clarified, aspectically filled into sterile packaging material and stored in cold storage.”

Here are basic steps involved in production:

1. Testing the raw milk

2. Standardization for fat and SNF

3. Weighing the ingredients

4. Heating the standardized milk into a Vat

5. Addition of sugar

6. Homogenization

7. Pasteurization

8. Cooling

9. Addition of flavor and colour

10. Filling into bottles

11. Storage

Method of Production

Packaging

The advancement in packaging techniques has helped the dairy companies in extending the shelf-life of the flavoured milk products and facilitating their transport to the markets. Several other techniques are being developed and adopted to enhance the shelf-life, flavour and texture of the products. For instance, silver-based micro-particles with bactericidal, antimicrobial, and self-sterilizing properties are added into the plastic packaging, which helps in increasing the shelf-life.

More recently, the carbonation method is being used to amplify the qualitative nutrition contained in milk. The method involves the carbonation of milk at 50 psi pressure for 30 seconds. It helps in inhibition of microbes, reduction in psychrotrophic count, contents of FFA and soluble nitrogen. With continuous innovation and adoption of advance technologies, dairy companies are now able to enter into the rural market.