Millet Flaking

Flaking is a process that is widely used for making flaked foods from cereals and millets. Flaked foods are widely consumed as breakfast meal or as snacks all over the world. Here, we’ll be talking about some of the popular flaked food products that are easily available in the retail stores.

3 Main Raw Ingredients

01. Cereal grains or millets

02. Salt and other flavoring agents

03. Vitamins & Minerals

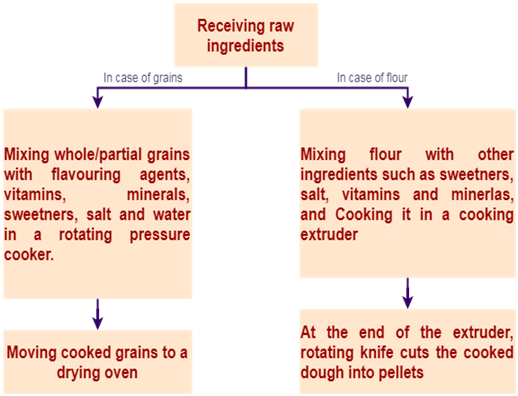

Basic Manufacturing Process

Stage I: Preparing the grains

Stage II: Flaking

“Apart from being used as a breakfast cereal, the crushed flakes can be a substitute for bread crumbs in recipes and can also be incorporated into many cooked dishes.”

Pearl Millet (Bajra) Flakes

Flakes can be prepared from pearl millet. Two recipes usually prepared from these flakes are pearl millet chewda(as a snack item) and pearl millet seasoned wet flakes (as a breakfast item).

Flaked Rice

Flaked rice (poha, chirwa) is a flattened carbohydrate rich edible food obtained by processing paddy. Flaked rice is obtained after soaking, roasting and flaking paddy.

Corn Flakes

Corn Flakes

Corn Flakes are used mainly as breakfast food along with milk. It is economical, convenient, nutritious and flavorful food suitable for daily consumption.

Nowadays, cornflakes are available in different flavours and packaging. For instance, strawberry corn flakes, cornflakes with honey and almond, etc

Multigrain Flakes

Multigrain flakes include flakes of various grains. Some of the popular ingredients are wheat flakes, sorghum flakes, rice flakes, rolled oats, sugar, honey, glucose syrup, salt, vitamins & minerals. These can be consumed with warm or cold milk.

Kellogg’s, Bagrry’s,Nestle’sNesPlus, Soulfull&Patanjali are some of the popular brands in the Indian market.